Discuss the rationale for lean standardized work and the differences between lean and conventional approaches

Design effective standardized work using the tools of motion economy, motion pattern analysis and human factors engineering

Design effective self and successor inspection strategies and integration within the standardized work process

Integrate source quality methods into standardized work systems

Describe strategies for process simplification such as kitting and minomi

Establish and document knack points in standardized work to insure effectiveness of the process and rapid learning by new team members

Use work elements training as a foundation for effective standardized work

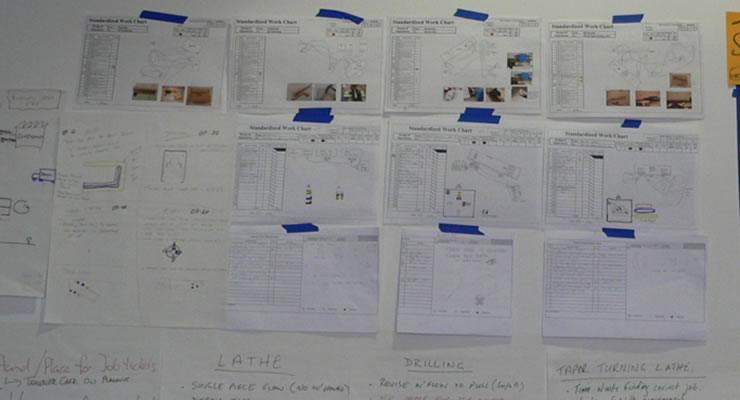

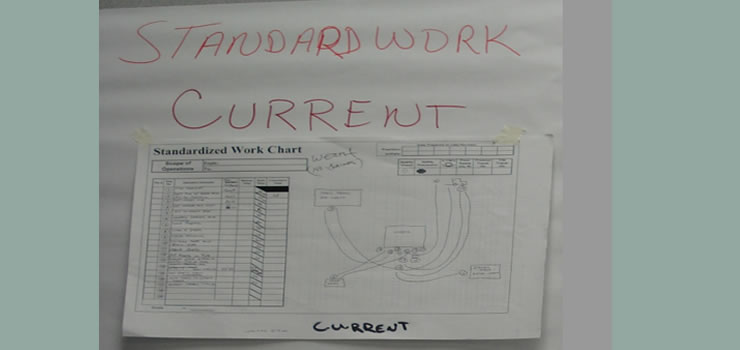

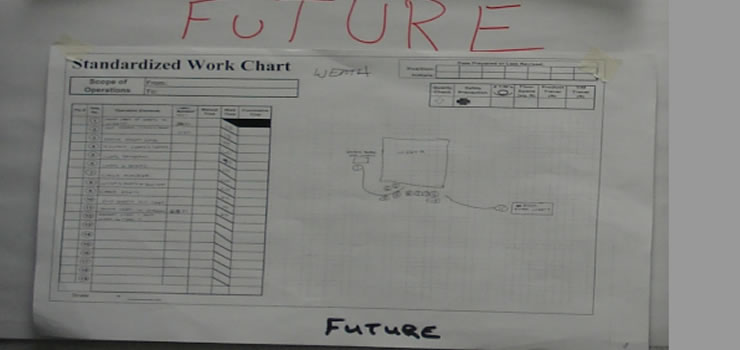

Conduct time studies and systems for documenting standardized work procedures

Develop an appropriate documentation system and practice for your organization

Involve employees in initial development of standardized work systems

Link standardized work with employee involvement systems such as suggestion systems

Apply practical line balance procedures, including mixed model systems

Classify processes based on cycle time variability and use in line design

Describe flexible work strategies that can be used to improve work balance and to absorb job-to-job work content variation with maximum efficiency