Comprehensive intervention focusing on changing the production schedule and shift pattern to reduce energy cost, implementation of visual controls and an internal milk-run system, reassignment of team members to value-adding positions, improved maintenance and process flow optimization

- Project timeline: 26 weeks

- Project cost: $145,711

- Project annualized savings: $2,589,689

- Return on Investment: 17.8

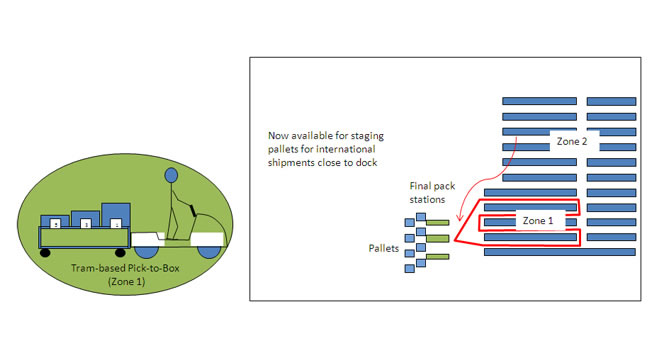

Australian Weaving Mills (AWM) is the home of textiles for brands such as Dickies, Dri Glo, Esprit Home, Koala Blue, The Cottonfield Collection and Tara Plus brands. In addition to their local manufacturing, AWM has an impressive sources side to meet the local needs. Operating in Devonport, Tasmania, AWM is today Australiaâs sole manufacturing of towelling products.

Australian Weaving Mills (AWM) is the home of textiles for brands such as Dickies, Dri Glo, Esprit Home, Koala Blue, The Cottonfield Collection and Tara Plus brands. In addition to their local manufacturing, AWM has an impressive sources side to meet the local needs. Operating in Devonport, Tasmania, AWM is today Australiaâs sole manufacturing of towelling products. After detailed discussions within the sector, a small number of strategic objectives have been identified to increase the sustainability and build internal problem-solving skills at AWM. The implementation of specific lean manufacturing processes is seen as essential to the management of Australian Weaving Mills. Mr. Steve Neilly, the Manufacturing Manager, has identified the weaving and hemming sections as lead areas for piloting the Competitive Manufacturing/ Lean Initiative.

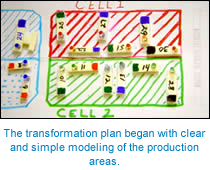

After detailed discussions within the sector, a small number of strategic objectives have been identified to increase the sustainability and build internal problem-solving skills at AWM. The implementation of specific lean manufacturing processes is seen as essential to the management of Australian Weaving Mills. Mr. Steve Neilly, the Manufacturing Manager, has identified the weaving and hemming sections as lead areas for piloting the Competitive Manufacturing/ Lean Initiative. In 2008, Mr Neilly and Mr Richardson attending the ILS Lean Practitioner Program (Grad Cert), which is held in Melbourne, Victoria. The Vocational Graduate Certificate requires the completion of 3 one week block of face-to-face training delivered over a 6 – 8 month period to enable time to complete enterprise based project work. The training program is driven by work place project development, where participants are required to apply their learning’s to their organizations.In February 2009, AWM held on-site training for 23 of their staff members to begin spreading the skills and knowledge of lean throughout the organisation. They underwent three two-day training sessions, covering the theory, principles and tools of lean. Between each training session, teams were provided with a workplace project where they could contextualize their learning’s to their own work areas. According to Mr. Neilly “The balanced mix of both theoretical and practical training has equipped the participants with the knowledge and skills to first recognize opportunities for improvement and then apply relevant lean tools, in the work environment, to realize and sustain those improvements.”

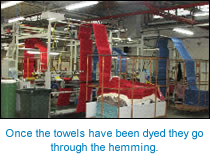

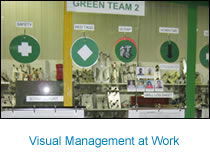

In 2008, Mr Neilly and Mr Richardson attending the ILS Lean Practitioner Program (Grad Cert), which is held in Melbourne, Victoria. The Vocational Graduate Certificate requires the completion of 3 one week block of face-to-face training delivered over a 6 – 8 month period to enable time to complete enterprise based project work. The training program is driven by work place project development, where participants are required to apply their learning’s to their organizations.In February 2009, AWM held on-site training for 23 of their staff members to begin spreading the skills and knowledge of lean throughout the organisation. They underwent three two-day training sessions, covering the theory, principles and tools of lean. Between each training session, teams were provided with a workplace project where they could contextualize their learning’s to their own work areas. According to Mr. Neilly “The balanced mix of both theoretical and practical training has equipped the participants with the knowledge and skills to first recognize opportunities for improvement and then apply relevant lean tools, in the work environment, to realize and sustain those improvements.” A four day Learning and Improvement Focused Transformation (LIFT) event then took place, allowing teams to analyze key areas of the business and apply lean tools such as 5S, visual controls, pull systems and set-up reduction principles. Moreover, teams were able to gain exposure to the different parts of the business that they would not have normally been exposed to, thus giving them a broader understanding of the operations involved in making their products. “The initial Lean training delivered by ILS at AWM has been highly successful with substantial, measurable gains being made in setup reduction time and WIP reduction in the specific target areas… and as a result has created a very

A four day Learning and Improvement Focused Transformation (LIFT) event then took place, allowing teams to analyze key areas of the business and apply lean tools such as 5S, visual controls, pull systems and set-up reduction principles. Moreover, teams were able to gain exposure to the different parts of the business that they would not have normally been exposed to, thus giving them a broader understanding of the operations involved in making their products. “The initial Lean training delivered by ILS at AWM has been highly successful with substantial, measurable gains being made in setup reduction time and WIP reduction in the specific target areas… and as a result has created a very

Following the “Go and See“ rule they learned early in these workshops, Skier’s Choice took benchmarking trips to companies considered world class in many performance areas. These included Toyota, Denso, Summit Polymers, Boeing, Subaru, Batesville Casket, Budweiser and even Walmart. They also took benchmarking trips to see other boat builders such as Malibu, Cobalt, Triton, Bryant, and SeaRay.

Following the “Go and See“ rule they learned early in these workshops, Skier’s Choice took benchmarking trips to companies considered world class in many performance areas. These included Toyota, Denso, Summit Polymers, Boeing, Subaru, Batesville Casket, Budweiser and even Walmart. They also took benchmarking trips to see other boat builders such as Malibu, Cobalt, Triton, Bryant, and SeaRay. After starting their second series of workshops in January 2007, they began teaching lean basics to everyone in the company. All operators were given 20 hours of lean education. These overview workshops were taught by graduates of the first certification series, eventually teaching all 350 team members. With the completion of this training, Skier’s Choice introduced the Lean Improvement Activity Sheet to capture the ideas the workforce had, and implement them more quickly. Within a matter of weeks, they received over 600 ideas from the workforce.

After starting their second series of workshops in January 2007, they began teaching lean basics to everyone in the company. All operators were given 20 hours of lean education. These overview workshops were taught by graduates of the first certification series, eventually teaching all 350 team members. With the completion of this training, Skier’s Choice introduced the Lean Improvement Activity Sheet to capture the ideas the workforce had, and implement them more quickly. Within a matter of weeks, they received over 600 ideas from the workforce. In late 2008, with the economy tumbling and boat sales dropping dramatically, Skier’s Choice was able to make people-friendly adjustments (no overtime, reduced the temporary workforce, temporary furloughs and leadership pay reductions) that allowed them to absorb the change quickly. With demand down, they redoubled their efforts, and further refined their production system, fully achieving single-piece flow in their manufacturing and sub assembly operations, further reducing inventories and saving a significant amount of money to use to keep the company healthy. Says Denning, “I’m convinced that by applying what we learned from ILS when we did is a major reason we were able to keep our doors open.” As a closely held company, total savings and return on investment figures are not released at the request of the company.

In late 2008, with the economy tumbling and boat sales dropping dramatically, Skier’s Choice was able to make people-friendly adjustments (no overtime, reduced the temporary workforce, temporary furloughs and leadership pay reductions) that allowed them to absorb the change quickly. With demand down, they redoubled their efforts, and further refined their production system, fully achieving single-piece flow in their manufacturing and sub assembly operations, further reducing inventories and saving a significant amount of money to use to keep the company healthy. Says Denning, “I’m convinced that by applying what we learned from ILS when we did is a major reason we were able to keep our doors open.” As a closely held company, total savings and return on investment figures are not released at the request of the company. Columbia Forest Products is North America’s largest manufacturer of hardwood plywood and hardwood veneer. The company, based in Greensboro, N.C., employs more than 2,100 people and operates facilities throughout the United States and Canada. Much of their hardwood plywood is used by cabinet makers and installed in homes across the continent.

Columbia Forest Products is North America’s largest manufacturer of hardwood plywood and hardwood veneer. The company, based in Greensboro, N.C., employs more than 2,100 people and operates facilities throughout the United States and Canada. Much of their hardwood plywood is used by cabinet makers and installed in homes across the continent. “Parthi has been absolutely critical in our success,” Duarte said. “He helped us look at our systems as a whole and helped guide us through our strategic planning.”

“Parthi has been absolutely critical in our success,” Duarte said. “He helped us look at our systems as a whole and helped guide us through our strategic planning.”

When Ed Furniss first heard about Lean, he didn’t see how it could apply to his company. “Lean seemed fine for the Toyotas and Motorolas of the world with their mass-production operations,” – said Furniss,Vice president and plant manager at Wabash Plastics, an Evansville, Indiana-based provider of high-quality custom plastic injection-molded parts. “But I didn’t see how it would work for a company like ours, where someone’s running a single machine, producing a part, putting it in a box and shipping it,” So, to get a better grasp of the Lean concept, Wabash Plastics sent its production manager to a class taught by ILS.

When Ed Furniss first heard about Lean, he didn’t see how it could apply to his company. “Lean seemed fine for the Toyotas and Motorolas of the world with their mass-production operations,” – said Furniss,Vice president and plant manager at Wabash Plastics, an Evansville, Indiana-based provider of high-quality custom plastic injection-molded parts. “But I didn’t see how it would work for a company like ours, where someone’s running a single machine, producing a part, putting it in a box and shipping it,” So, to get a better grasp of the Lean concept, Wabash Plastics sent its production manager to a class taught by ILS.

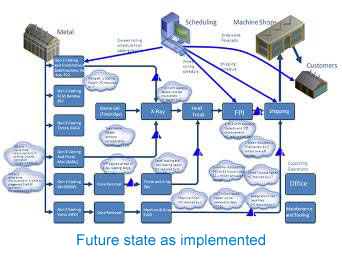

Comprehensive intervention improving capacity of labour-intensive X-ray and FPI inspection lines, reducing operating shifts from 4 to 2. Improvement of casting OEEs from 50% to 80%, enabling additional reduction of operating shifts. Plant manager coaching to establish highly effective problem solving skills within the organisation. Participation of the entire workforce in LIFTs, averting the imminent closure of the operation. Major new contracts from European luxury automotive producers have been realized.

Comprehensive intervention improving capacity of labour-intensive X-ray and FPI inspection lines, reducing operating shifts from 4 to 2. Improvement of casting OEEs from 50% to 80%, enabling additional reduction of operating shifts. Plant manager coaching to establish highly effective problem solving skills within the organisation. Participation of the entire workforce in LIFTs, averting the imminent closure of the operation. Major new contracts from European luxury automotive producers have been realized.