The Lean way

- P.O. Box 8173 Louisville, Kentucky 40257-8173 USA

- Phone: + 1-502-322-6567

- [email protected]

Advanced Lean Systems Design

- Home

- Advanced Lean Systems Design

- Skills Development Workshops

- Advanced Lean Systems Design

- Design of Experiments

- Value Stream Mapping & Design

- Facilitation Skills for Building Teams

- 5S & Visual Control

- Standardized Work and Source Quality

- Quick Changeovers / Set-up Reduction

- Pull Systems

- Problem Solving (C4)

- Lean Work Cells and Lines

- Daily Management Systems

- Learning Through a Suggestion System

- Executive Education

- Lean Leader Certification

- Lean Systems Certification

- MBA Program with a Lean Focus

The goal of this program is to build a stronger internal support team with the knowledge, skill, ability to assess existing operations, to develop highly effective lean restructuring plans or facility layouts, to develop strong supporting systems, such as internal logistics or production control systems and to lead teams to execute these plans.

The specific content of this 2-week workshop will be tailored to meet your team’s specific needs. An example curriculum follows:

Logistics

We conduct this workshop only onsite for individual companies. It is often conducted with two or three rapid improvement LIFT events to rapidly bring change agent skills up to a high level. This workshop requires no special facilities. The ideal meeting space is approximately 30’ x 30’.

Lean System Design

The Lean Operational Model

Explains the structural requirements of lean operation and explains proper integration of lean technical, managerial and human systems through a series of hands on simulations. This knowledge is foundational to successful operations restructuring efforts.

Survey of Basic Lean Tools

A brief review lean tools including 5S, visual control, setup reduction, standardized work, source quality and emphasizing their role in operations restructuring. Assumes prior knowledge of each participant.

Pull Production Control Systems

This covers the theory, functionality, and implementation of pull production control systems. All standard types of pull systems are covered along with CONWIP, an alternative pull strategy useful in higher variability systems. Theory and operational aspects of all systems are demonstrated through hands-on, discovery learning simulations and system design exercises. Additionally, the use of visual control boards for flexible job dispatching, pull/scheduling interfacing and supporting logistics systems are covered in detail. Leveling algorithms and buffer sizing calculations are covered.

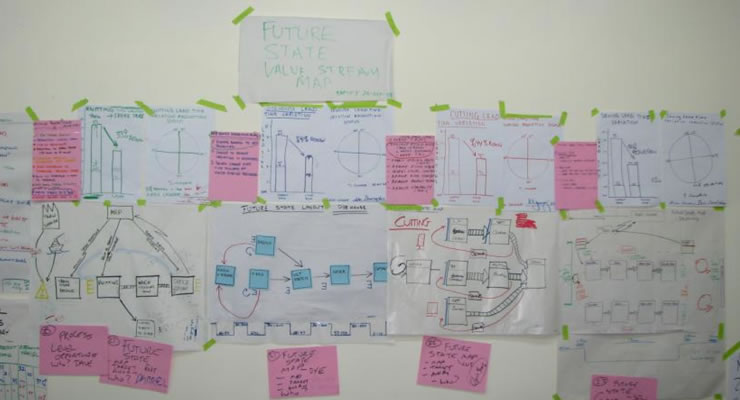

Value Stream Mapping

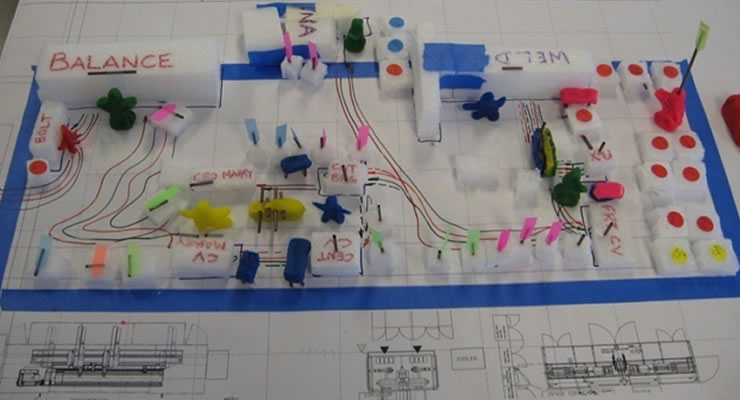

This covers value stream mapping as a tool for planning overall restructuring efforts. The treatment, which is far deeper than Learning to See, addresses basic product family and value stream definition, mapping conventions, executing VSM events, current state mapping and future state mapping. Issues such as cell formation, strategic use of parallel structures, kitting and kitted flow, structures to improve system-level synchronization of material flows, realistic capacity calculations, design of buffering systems and detailed integration of production control and logistics systems are covered in depth. Students execute a complex, detailed case study with a model factory (based on real world factories we have restructured) to learn how to apply this important tool in detail. The case study requires determination of cells, detailed address of necessary supporting kaizen activities, production control design, capacity analysis, proper dealing with monument operations, consideration of alternative pacemaker locations and various production control and scheduling design issues.

Extended Enterprise-level Restructuring

Value stream mapping concepts from Course 1 are extended to the extended enterprise level, including supporting operation such as engineer-to-order and supply chain/logistics structuring. A case study involving restructuring of an integrated sales, design-to-order, component procurement, scheduling and manufacturing case is executed by the students, extending their learning from the previous class to the total enterprise level where white collar processes and transactional systems are important. This case also addresses elimination of waste in information flow processes and addresses financial performance measurement in a lean system.

Production flow Analysis

The use of this tool for defining parts families in complex high variety/low volume situations is addressed in detail, including case studies.

Waste and Factory Physics

A very in-depth treatment of waste that develops a sophisticated eye for identifying and eliminating it. This treatment incorporates factory physics concepts and illustrates major concepts through real world cases that the teachers have encountered in their professional practice.

Target Audience

This program is designed for teams of experienced lean specialists. This is appropriate for your corporate lean team, six sigma black belts, or specialized tiger teams assigned to the most pressing problems an organization faces.